Management policy

The screw factory Tweer & Lösenbeck was founded in 1919 and has been located in Lüdenscheid ever since. It has been owned by the Pithan family since the 50s. As a pure contract manufacturer, Tweer & Lösenbeck develops and produces small screws and fasteners for the most demanding requirements – several million pieces a day.

For Tweer & Lösenbeck, quality is not just a buzzword, but a consistent process with a decisive goal: Zero defects” in every single step of the production process! The company’s position as a quality and innovation company is to be maintained and expanded in the future as well.

1. improving customer satisfaction

The primary goal is to maintain and further develop customer satisfaction. To this end, the company uses machines and mastered processes which take into account the high demands on the products to be manufactured and the careful handling of the environment and resources.

The internal and external interested parties of Tweer & Lösenbeck have been identified and the relevant topics are known. These issues are regularly monitored and evaluated with regard to possible risks and opportunities. Even in exceptional situations, the supply of customers with objection-free products can therefore be ensured.

2. improvement of processes, products and supply capability

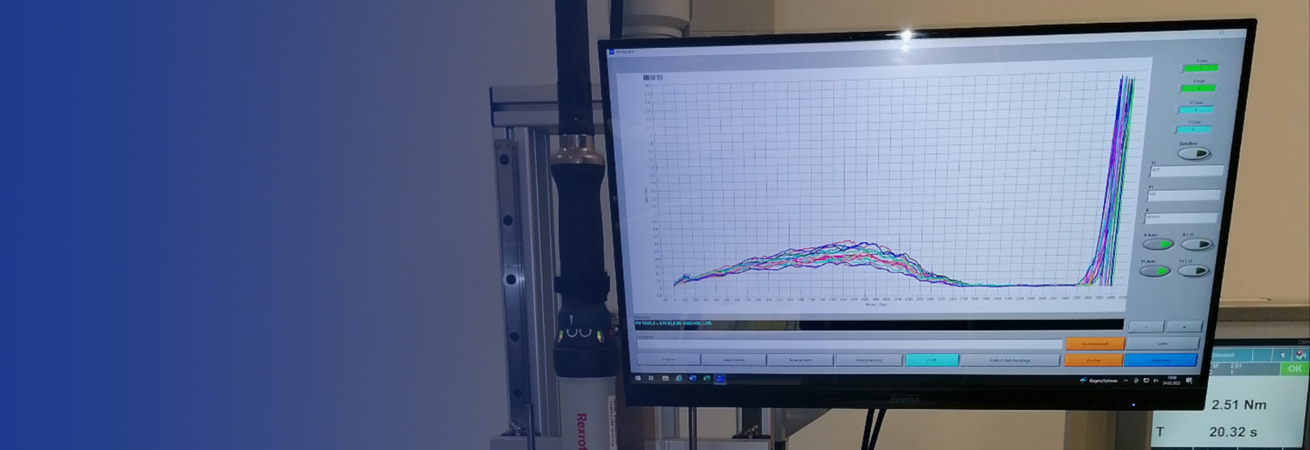

Procedures are applied at all stages of product development which make it possible to detect faults easily, quickly and cost-effectively and to continuously improve the quality and environmental performance of processes and energy efficiency. All activities of the company that are directly or indirectly related to the production of high-quality fasteners are monitored and assessed for their quality and environmental impact.

The impact of new products or processes on quality and the environment is tested and evaluated by means of trial production. Further improvements are systematically derived from the findings. All employees are motivated and encouraged to participate in the process of continuous improvement.

3. improvement of employee competence/ satisfaction

Employees participate in all phases of product development, from contract review to product delivery, to improve quality and environmental performance, as well as energy efficiency. The expertise and skills available within the company are defined and ensured by appropriate measures.

4. improvement of the integrated management system

The consistent application of the management system is intended to secure the existence of the company and the existence of jobs in the long term, thus ensuring the supply of satisfied customers with continuously improved products and processes from Tweer & Lösenbeck.

5. gentle production processes

The production processes are designed in such a way that they correspond to the available state of the art. This is to ensure that production is as resource-efficient as possible, with low emissions, energy consumption and noise. Tweer & Lösenbeck constantly adapts its production techniques, products, aids and packaging to the latest findings and needs.

6. improving environmental performance

For years, Tweer & Lösenbeck has been one of the first companies to be certified according to the environmental standard ISO 14001. The aim is to optimise environmental performance and reduce environmental pollution.

Legal obligations and other requirements are fulfilled, and environmental aspects and key environmental figures are regularly determined and reviewed. All areas of the company are critically examined and continuously improved ecologically.

All employees of Tweer & Lösenbeck are involved in the implementation of the environmental management system and the necessary resources are provided.

7. optimisation of energy consumption and energy efficiency

The aim and obligation is to reduce energy consumption continuously in the long term and to increase energy efficiency. For implementation, an energy management system according to ISO 50001 was introduced.

Legal obligations and other requirements are fulfilled, and energy aspects and key energy figures are regularly determined and checked. All areas of the company are critically examined and projects to improve energy-related performance are derived and implemented.

All employees are involved in the implementation of the energy management system and the necessary resources are provided.

8. minimising environmental and energy-related risks

Employees are involved in environmental and energy activities and informed about the results. Employees are aware of the existing risks regarding safety, health, environment and energy. Possible risks are taken into account in the emergency plan.

9. code of conduct and ethics

As part of corporate responsibility, a code of conduct and ethics was drawn up, announced to employees and communicated to the public via the company’s website. For Tweer & Lösenbeck, these guidelines set out the common basis of values with regard to social and societal responsibility and fair competition.

10. occupational safety

Tweer & Lösenbeck strives for zero industrial accidents and does everything in its power to protect employees from occupational accidents and illnesses. The focus is on identifying and determining risks, and on eliminating them.

All our certificates are available in German, English and French. They are combined into one document by clicking on the corresponding certificate

Smallest screws in huge quantities with consistently high quality

Smallest screws in huge quantities with consistently high quality