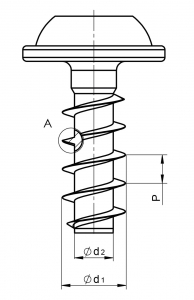

Screws for thermoplastics – TLK

- Long service life of the screw connection

- Transmission of high tightening torques

- Tenfold repeat screwing possible

- Optimum self-locking

- Elimination of the thread cutting operation

- Shorter cycle times with automatic screwing

- Large thread overlap between screw thread and component

- Low screw-in torques due to low material displacement

Smallest screws in huge quantities with consistently high quality

Smallest screws in huge quantities with consistently high quality