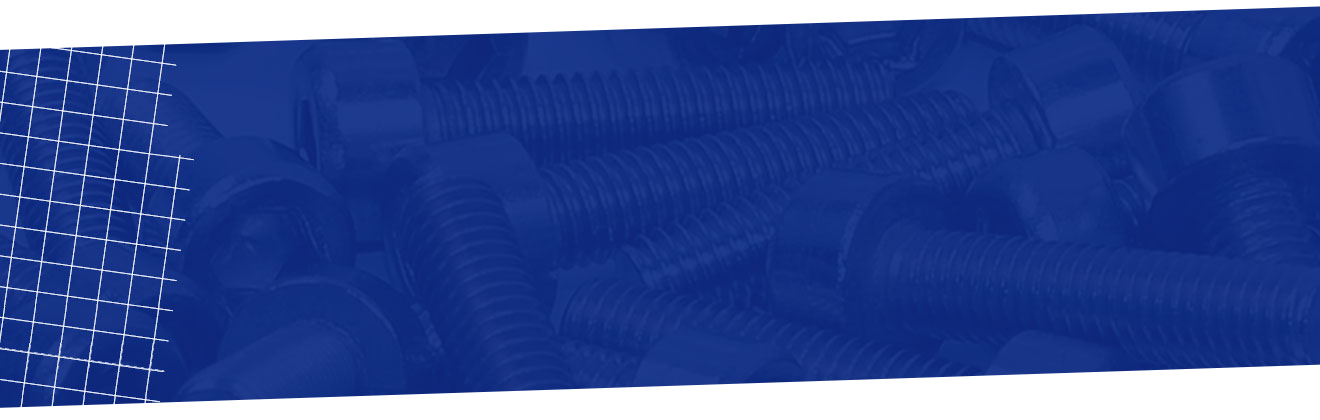

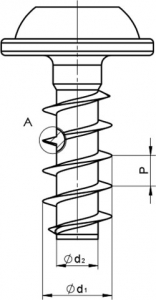

TRIFORM™

- low fear torques

- high thread load capacity

- proven a million times over

- cost-saving

- up to Ø 4.0 millimetre

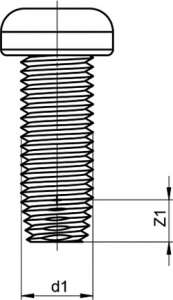

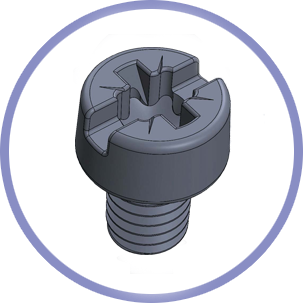

TRIFORM™ DB

- high axial load capacity

- circular cross-section

- for sheets up to 950MPa tensile strength

- increased load capacity due to reinforced collar formation

- up to Ø 4.0 millimetre

Smallest screws in huge quantities with consistently high quality

Smallest screws in huge quantities with consistently high quality